Sheet piles are generally capped for Aesthetic purposes. Bracket fixed on interlocks of U type sheet piles - SWL.

Sheet Pile Capping Beam Formwork Sheet Pile Concrete Cap

Sheet pile capping beam formwork.

. What would your design load be on the cap beam. There are three models of Redeb bracket - the RSB500 RSB600 and RSB700. Bracket fixed on any inclined webs of U or Z type sheet piles having a minimum included angle of 55º - SWL.

Sheet Pile Design by Pile Buck and the online help for SPW 911 explain how that is properly applied. They allow to spread the load on sheet pile and to concentrate them onto the tie bars. Shear load must be applied by continuous beam or waler on the face of the wall.

The guidance is based on the present state. By Ensoft Inc Austin TX January 2015 This report presents the recommended structural capacities for Truline composite wall sections and a summary of design methods commonly used to design cantilevered and anchored sheet pile structures. The concrete cap serves to mask the inevitable irregularities in sheet pile length penetration depth and line.

Sheet Pile Cing Beam Design. On any Z Frodingham type sheet pile will be 1500 kgs. Design of Sheet Pile Walls Using Truline Composite Wall Sections Design Methods and Examples.

Engineering and Design DESIGN OF SHEET PILE WALLS 1. The foundations support the structures transferring their load on layers of soil or rock that have sufficient bearing capacity and adequate settlement characteristics. The total length of the sheet pile wall is h d 10 146 246.

Waling beams are used in combination with tie bars for anchoring sheet pile walls. Waling beam systems Steel system installed on sheet pile walls. Greener The Fast-Form beam system will reduce your carbon footprint by over 80 against timber formwork and by.

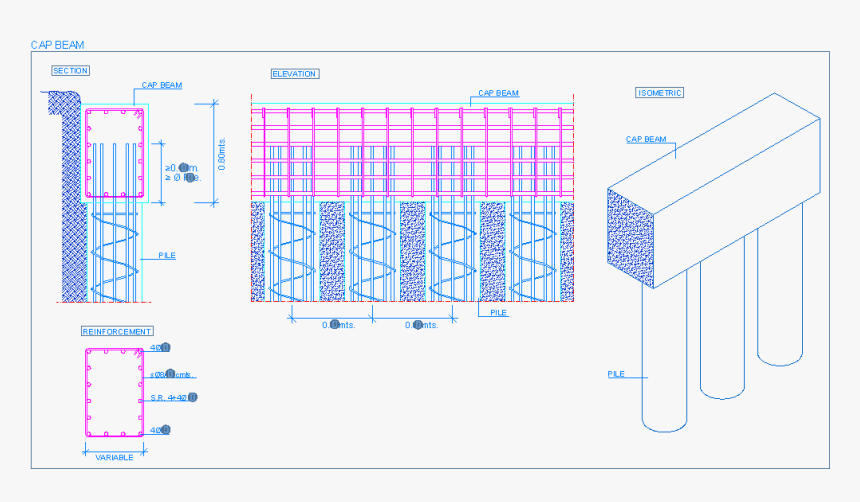

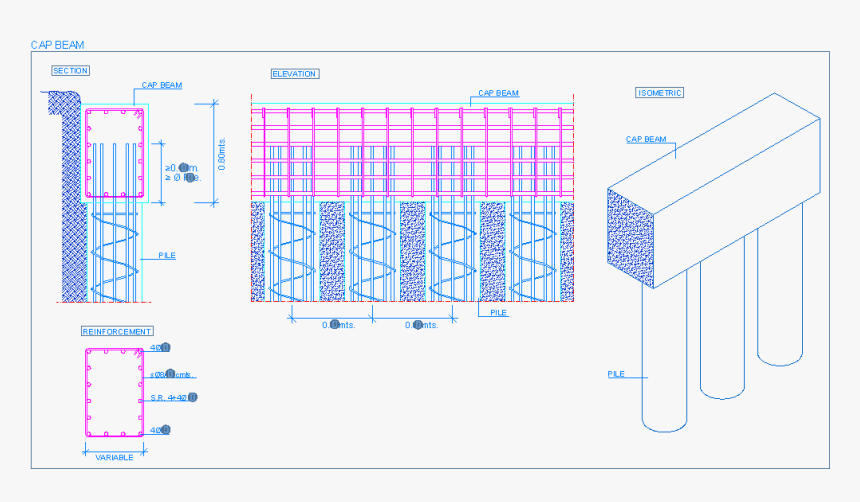

Pile Cap Design Excel Sheet A pile cap is a thick concrete mat that rests on concrete or timber piles that have been driven into soft or unstable ground to provide a suitable stable foundation. How to construct a capping beam. How to mark the lines and keep setting out dutiesCon.

Download excel sheet for designing a pile cap. Design of Sheet Pile Walls Using Truline Composite Wall Sections Design Methods and Examples. Allowable Moment Capacity in-lbsft Bending Stiffness EI lbs-in2ft 53100 25080000.

Non-alloy cold-bent steel sheet pile and now ranks among leading cold-bent steel sheet pile manufacturers of the world at present. This manual provides information on foundation exploration and testing procedures analysis techniques allowable criteria design procedures and construction consideration for the selec-tion design and installation of sheet pile walls. They may also be used as a support for a railing or safety barrier.

Each sheet pile supports the same load as long as the wall height soil properties and surchargre loads remain the same. ANGLE OF SHEET PILE WEB. The RSB500 RSB600 models are designed to.

Waling beams and tie bars therefore form a system with strong compatibility with one another. Fast-Form provides complete solution for different types of pile cap slab base beam wall and sheet pile capping beam formwork whether they come in straight or radius single or double sided. Sheet pile capping beam design example.

Ad Sales rental of steel sheet and H-piling through 7 locations in US. The pile caps span to thickness ratio must be not excess than 5. Furthermore Grand has built up its own brand in the field of steel sheet pile and its GP series cold-bent steel sheet piles have been used in a number of key.

For example a sheet pile wall is designed on a per linear foot basis. It usually forms part of the foundation of a building typically a multi-story building structure or support base for heavy equipment. Therefore if you add a cap beam to the sheet piles it will not perform any useful structural function.

The Fast-Form sheet pile capping beams system can in a lot of cases be fitted from one side or from a cherry picker without the need for a crane. For our purposes we will further simplify the process by increasing the entire penetration below the dredge line by 20 thus d 122 02122 146. The pile cap must be relatively rigid to transfer the load to the pile section to downwards.

A pile cap stands for a compact concrete material that is supported with concrete or timber piles driven into soft or unsettled ground to build up a perfect durable foundation. Posted on May 28 2019 by Sandra. This means that the maximum SWL.

The thickness must not be below 500 mm and its decreased to the 300 mm on the peripheries. This technical supplement describes typical applica-tions for cantilever sheet pile wall in stream restora-. The use of sheet pile types of walls sheet pile materi-als classical method of design for wall stability struc-tural design specification and installation of sheet pile for stream restoration and stabilization projects.

Sheet pile design ysis soil mechanics and geotechnical ering cantilever sheet pile walls design of steel sheet piles dynamic response of soil pile structure. In pile cap construction the clear cover must be more than 40 mm. What do you need to know during the capping beam construction process.

This system can efficiently bolts together to facilitate casting kickers plinths hang bolts. It generally develops part of the foundation of a building specifically a multi-story building structure or support base for heavy equipment. Fast Form Bracket System offers complete slab wall sheet pile capping formwork Solution.

Faq Arcelormittal Steel Sheet Piles

Capping And Base Beams Measurements In Millimetres Download Scientific Diagram

Figure 4 13 Installing A Concrete Cap And Face On A Steel Sheet Piling Wall Concrete Steel Sheet Installation

Figure 4 13 Installing A Concrete Cap And Face On A Steel Sheet Piling Wall Concrete Steel Sheet Installation

Retaining Detallesconstructivos Net Bored Capping Beam Sheet Pile Hd Png Download Transparent Png Image Pngitem

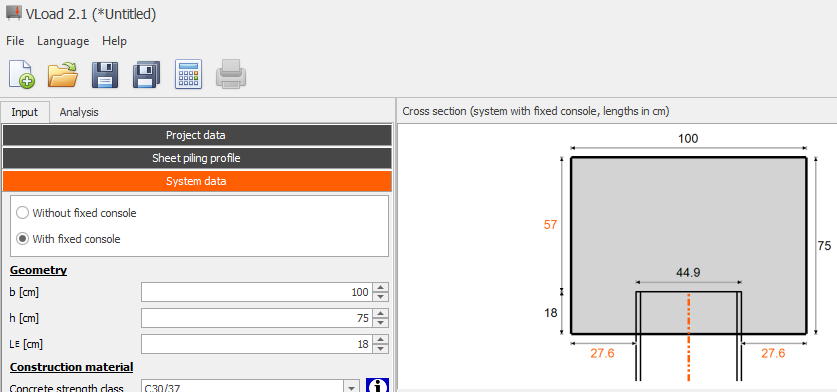

تويتر Arcelormittal Piling على تويتر Vload Your Solution To Design The Capping Beam Of Steel Sheetpiles Https T Co Lmkreesyf3 Http T Co Igjoatx7ux Http T Co 19a5ifgnwx

Sg Sheet Piling Your One Stop Steel Sheet Piles Solution Specialist

0 comments

Post a Comment